2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register, manage and order repair for your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

Mirka's Gear Chamfering solution is focused on small and medium size batch volumes from one piece to up to a few hundred of the same gears per year. The solution can process industrial gear wheels from 100mm to up to 1500mm, which typically are used in marine, offshore, energy, mining, and many other types of industrial solutions.

Especially when dealing with a high mix of products and small batch sizes, the chamfering and finishing of gear wheels are very often done manually. Our solution automates this normally very messy and mundane manual work process. The automated process ensures better and more consistent quality. In addition, the work environment is much safer and more comfortable for operators.

Dedicated production cell and tooling for gear chamfering and finishing

Designed for high mix production

Unique parametric chamfering toolpath calculation

No programming skills required for new part programming

Setup time for new part less than 10 minutes

Superior chamfer geometry and quality

Mirka's Gear Chamfering solution is an extremely flexible production cell with quick and easy programming. The programming time of a new gear wheel is less than 3 minutes and set-up can be completed without any robotic programming skills thanks to the easy-to-use user interface for parameter entry.

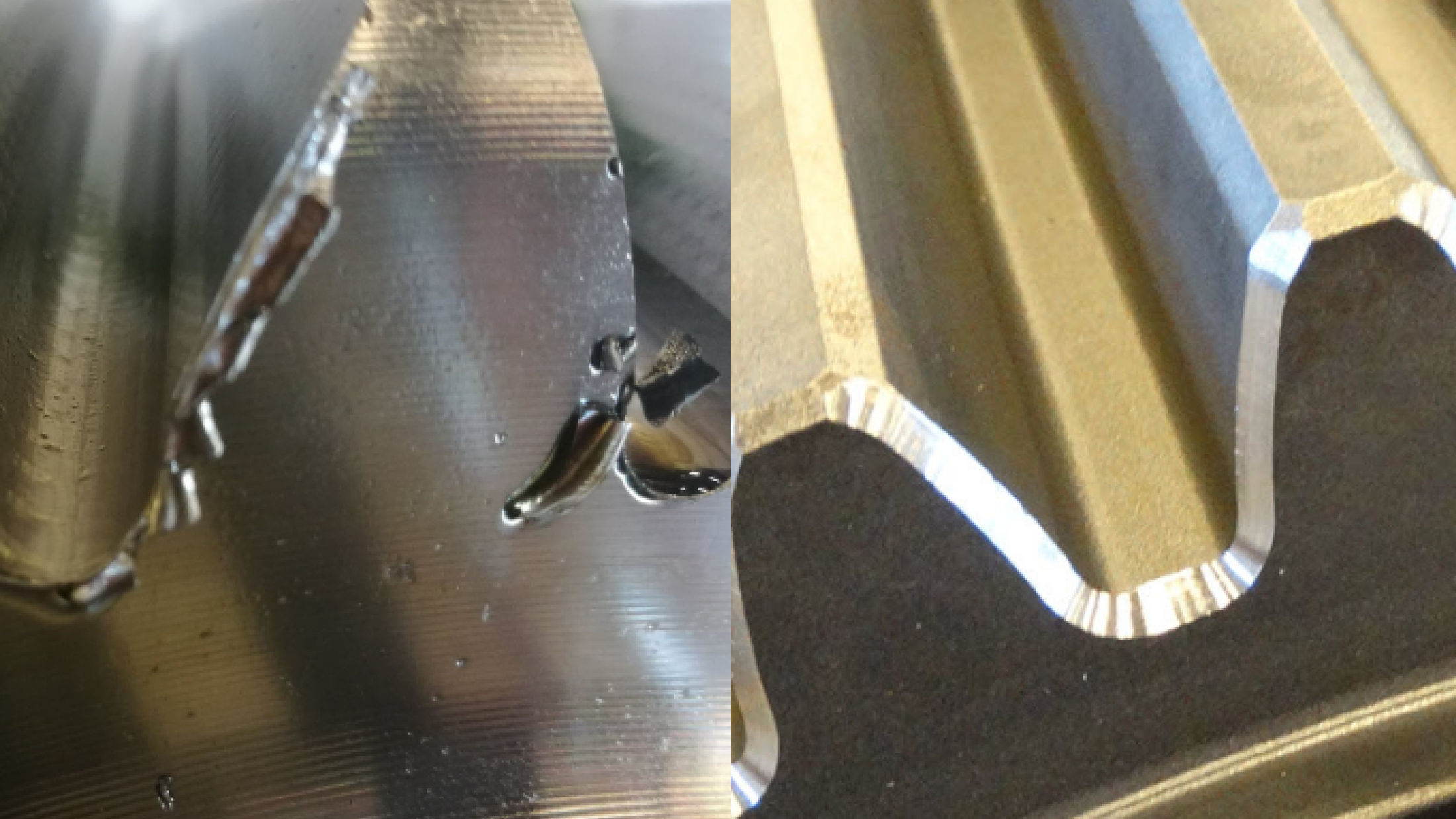

Machined gear wheel with burrs

Gear wheel design parameters entry and automatic probe measurement

Automatic robot path generation based on parameters and measured values

Robotic chamfering and finishing

High quality, chamfered and finished gear wheel