2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register, manage and order repair for your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

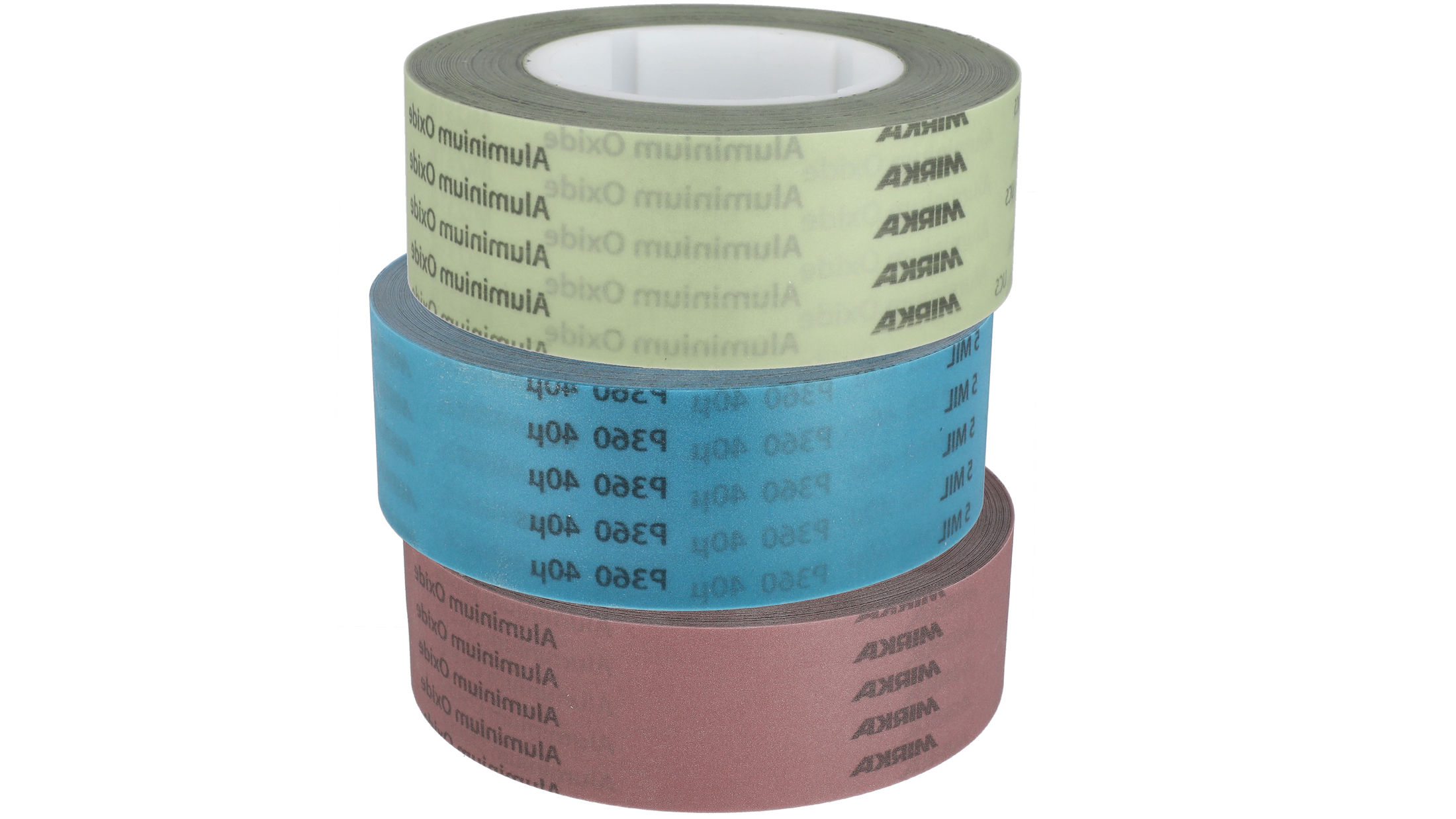

Introducing Mirka MI231B abrasive film for enhanced durability and performance

Mirka MI231B abrasive films are engineered to address the critical challenges of powertrain production, including frequent roll changes, machine stoppages, and inconsistent results. Featuring advanced anti-slip technology, these films ensure extended roll life, reduced interruptions, and increased operational efficiency.

Specifically designed for demanding applications such as crankshaft and camshaft polishing, as well as roller conditioning, MI231B delivers consistent, high-quality finishes that improve throughput and reduce production costs.

Optimize your powertrain manufacturing processes with MI231B — the reliable solution for precision and performance.

Abrasive film product designed for the coarse and fine polishing of powertrain components. The product is more aggressive than standard aluminium oxide films, but produces a fine surface scratch pattern. Fast cutting and resistant to surface loading, MI231C is sure to shorten cycle times.

Abrasive film product designed for the fine polishing of powertrain components. Fine cutting and resistant to surface loading, MI231A produces a consistently extra-fine surface scratch pattern.

Mirka® Cafro vitrified CBN superabrasive wheels are the right choice to make your grinding operations more efficient. See the benefits of faster grinding times, improved wheel life, increased dressing intervals, and superior thermal control reflected in a reduced cost per component.

Our vitrified CBN wheels are available in a wide range of customizable dimensions, up to a diameter of 600mm as single-rim wheels and 900mm as segmented. Standard sizes can be produced with an improved delivery time. We offer wheels with steel, bakelite, and carbon fiber bodies.

Stay informed and inspired with exclusive updates

Discover surface finishing solutions, tips, and the industry trends – for professionals like you.