2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register, manage and order repair for your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

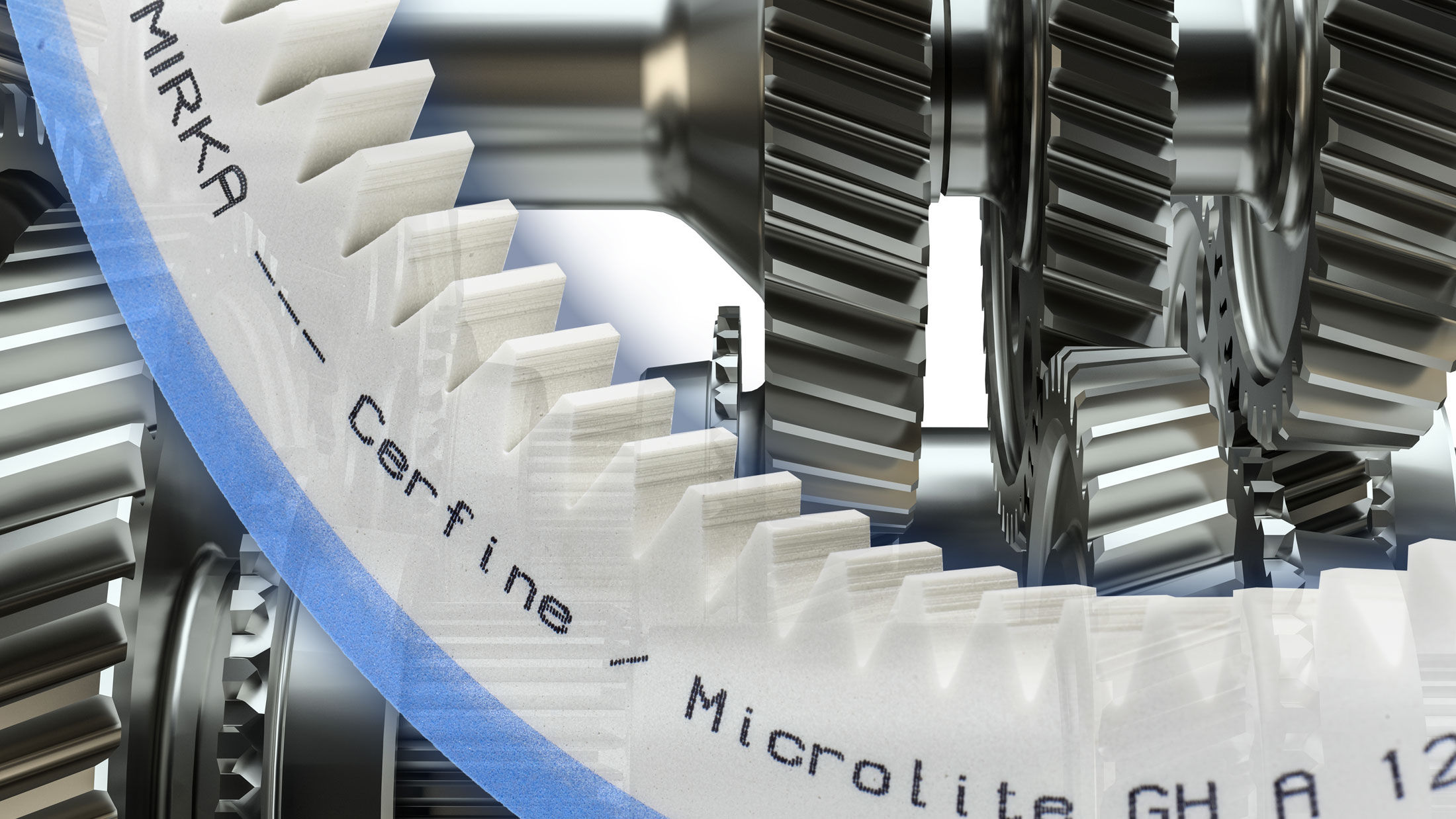

Precision and consistency

The grinding process plays a crucial role in the fulfillment of the precise requirements in shape and dimensional accuracy, topography, and subsurface properties. Only uncompromising accuracy in hard-fine grinding enables excellent surface quality.

Every tooth counts, Mirka Bonded Abrasives guarantee the precision and consistency modern transmission systems demand.

From profile, worm grinding, honing and polishing to finishing of all other surfaces

Every process supported by Mirka Bonded Abrasives is designed for consistency, controlled wear, and optimized performance.

Gear Honing: Achieves the best surface quality and low noise emission for high-performance gears.

Continuous Generating Grinding: High productivity for small to medium module gears and good surface quality.

Profile Grinding: Ideal for large modules or small batches with excellent form control.

Gear Bore and Face Grinding: Dressable tools ensure precise tolerances on bores, ODs, and other surfaces of the gear.

Special Gearing: Tailored solutions for non-standard geometries and demanding materials.

Cost-effective solution for grinding of gears without special demands.

Powerful all-round specification.

Excellent cutting performance coupled with very good profile stability.

Highest performance class: solution with highest cutting performance and tool life.

Innovative bond systems engineered for cooler, faster, and more consistent gear grinding results

For the highest performance and in thermally sensitive processes, we recommend our innovative bonding systems.

Advantages

These technologies deliver proven improvements in thermal workpiece load, productivity, and tool life across all gear grinding applications. We always aim to find the most economical solution for our customers, considering all relevant factors such as dressing, tooling, and machine costs to reduce overall costs-per-workpiece.

Questions and expert answers

What makes gear honing the best choice for ultra-smooth, low-noise gear finishing?

Compared to other industry-relevant gear grinding processes, gear honing generally achieves the best surface quality. This makes the process indispensable when machining gear parts with high demands on noise emission and power density, for example in e-mobility or in the commercial vehicle sector. Furthermore, honing can be used for workpieces with interference contours that may not be machined with other grinding processes.

The tools configured and produced by us are essential for this. With vitrified and resin-bonded honing rings you can rely on particularly wear-resistant and highly productive solutions. If that still is not enough, you can use our microlite honing rings to further increase surface quality. When polishing in a honing process, you can easily achieve Rz values significantly lower than 1μm and high bearing ratios of the surface. The desired surface result is guaranteed.

How does continuous generating grinding increase productivity in high-volume gear manufacturing?

Bulk production of gears with a small to medium module is most productive with a continuous generating gear grinding process. With our high-performance bonds and microlite polishing tools, the process focus can be shifted between maximum productivity and optimal surface quality thanks to polished tooth flanks.

Mirka combination tools are a special feature. They combine a vitrified part for the preliminary grinding process and an elastic microlite part for the final polishing of the tooth flanks. Both parts are connected with an innovative, patented connection technology that also allows very high cutting speeds. With these combi tools, you can run highly productive polishing processes, as there is no need for time-consuming tool changes or moving the component to a separate machine. Furthermore, the customized tool specification always allows to perform the polishing process in one single stroke.

Why is profile grinding ideal for large-module or small-batch gear production?

If you grind gears with large modules or in small quantities, profile grinding is the perfect solution. The individually profiled tools create the corresponding counter profile of the grinding wheel on the workpiece. As high infeeds are often used and thus lead to high contact lengths, the tool is subjected to particularly high thermal loads. By using a highly porous grinding wheel, cooling can be improved and profile stability of the tool can be maximized thanks to extremely wear-resistant bonds.

What solutions are available for non-standard gearing and complex gear grinding applications?

If standard grinding processes and the corresponding tools cannot be used, have reached their limits or the target parameters cannot be achieved, we will work with you to find solutions outside the standard range. Please contact us to know more.