2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register, manage and order repair for your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

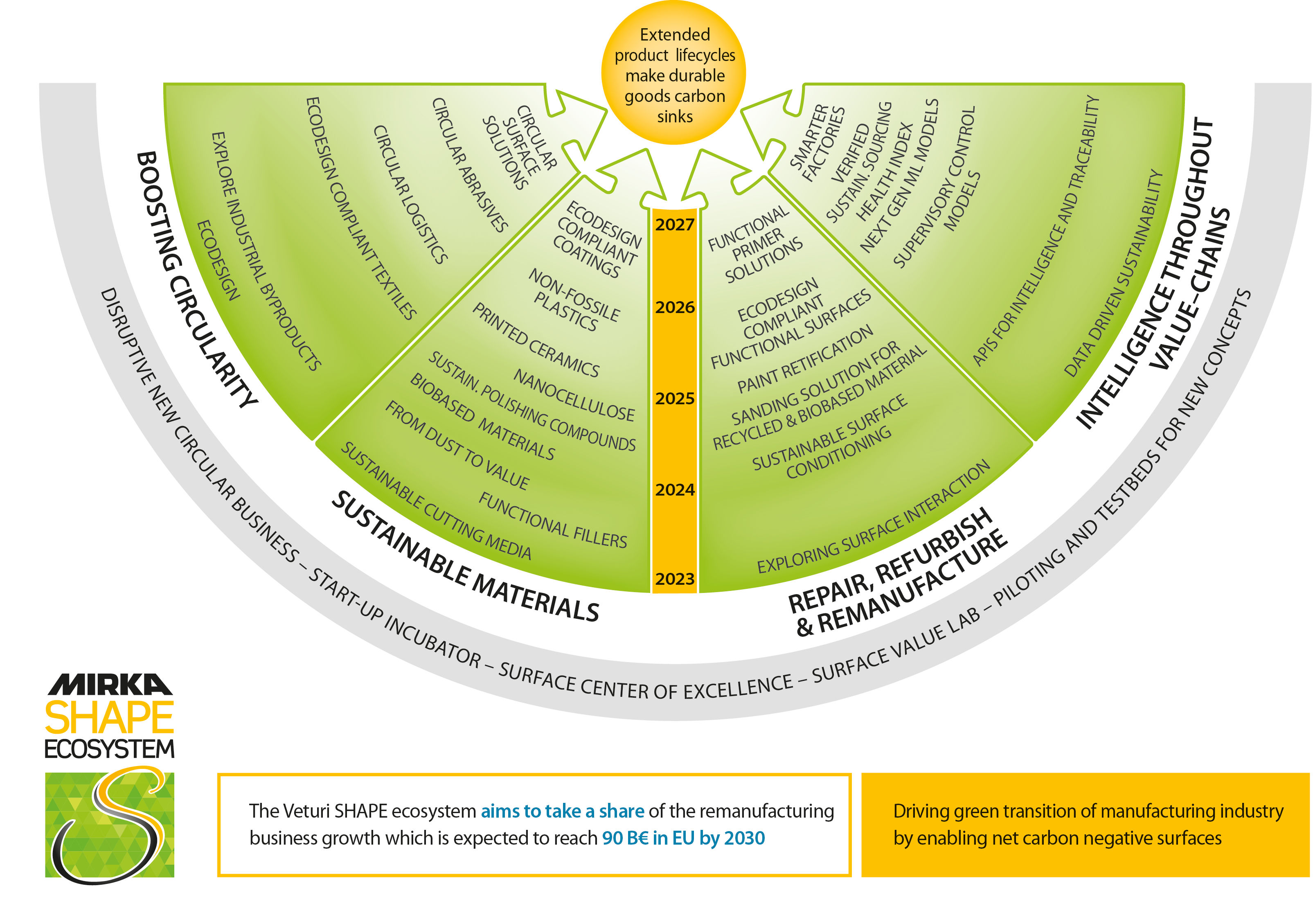

Rapid economic growth, urbanization and excessive material usage pose a significant threat of an increasing manufacturing footprint. Despite this, Mirka sees an opportunity to develop new innovative solutions to support the green transition in cooperation with the Finnish industry. The aim is to create a cross-industrial ecosystem to develop solutions for the remanufacturing and construction industries, contributing to a net carbon negative impact.

Driving Green Transition of Manufacturing

Business Finland has granted 10 million euros in development funding for the Mirka SHAPE project in the challenge competition as well as 20 million euros to the ecosystem companies surrounding the project. This is a unique project and the first of its kind in Finland.

The Veturi SHAPE ecosystem aims to take a share of the remanufacturing business growth which is expected to reach 90 B€ in the EU by 2030.

In the future Mirka’s surface finishing solutions and the SHAPE ecosystem can together decrease the carbon footprint of the European industry by 100 Mt, creating export opportunities worth several billion for the Finnish industry.

Mirka is the driver of the project, and the surrounding ecosystem consists of tens of actors from small-scale industries to large corporations, research institutes and universities. The launch event of the project will take place in the spring of 2023.

Mirka With SHAPE Ecosystem

Roadmap

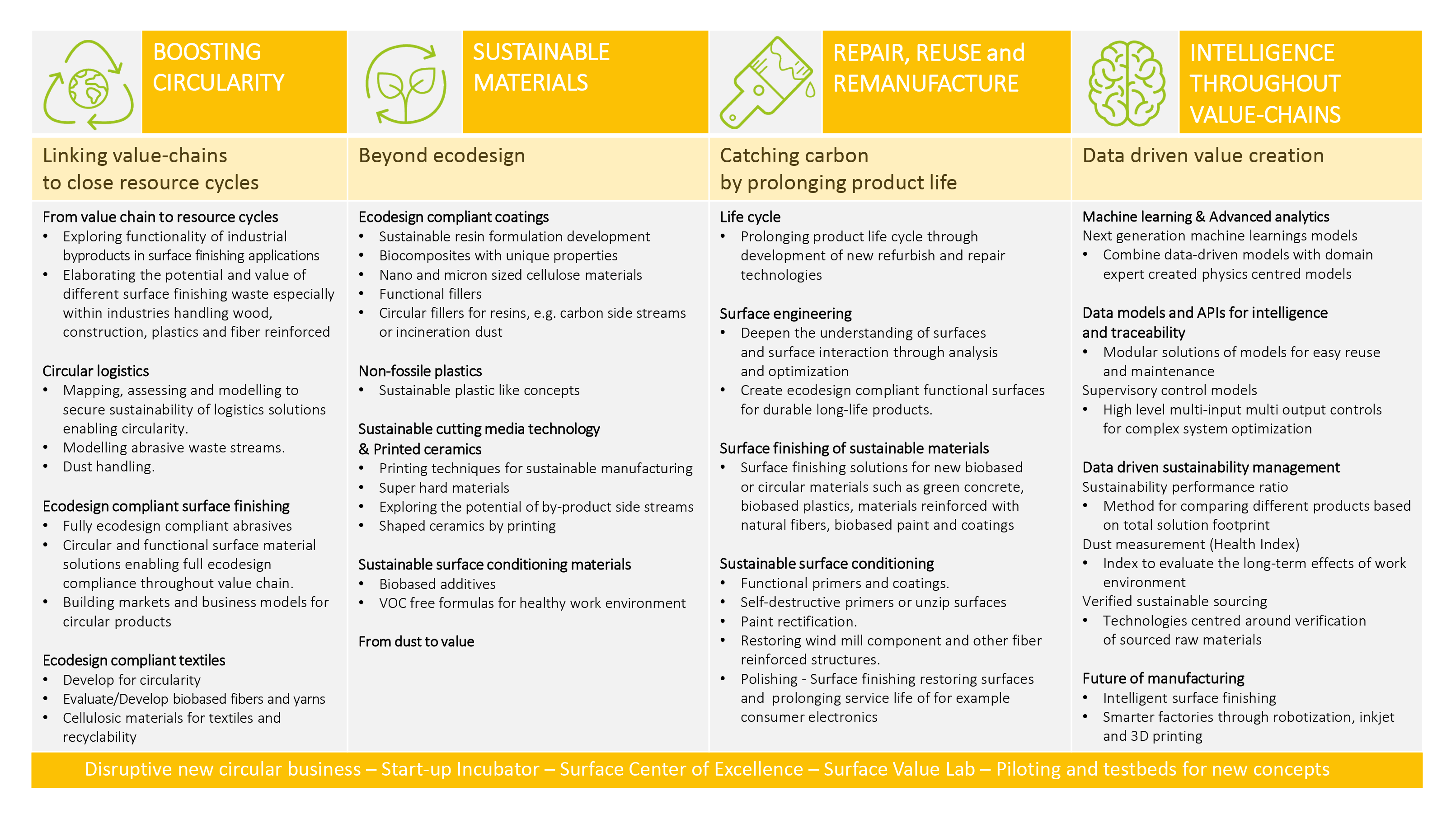

Boosting Circularity

From value chain to resource cycles

Circular logistics

Ecodesign-compliant surface finishing

Ecodesign compliant textiles

Sustainable Materials

Ecodesign compliant coatings

Non-fossil plastics

Sustainable cutting media technology & Printed ceramics

Sustainable surface conditioning materials

From dust to value

Repair, Reuse and Re-manufacture

Life cycle

Surface engineering

Surface finishing of sustainable materials

Sustainable surface conditioning

Intelligence Throughout Value-Chains

Machine learning & Advanced Analytics

Data models and APIs for intelligence and traceability

Data-driven sustainability management

Future of Manufacturing

With Net Carbon Negative Surfaces

Co-operation beyond industry borders is a natural part of Mirka’s corporate culture. We are now happy to invite all companies and research organizations that share our vision to take part in this development project and build up the complete ecosystem

Research & Development Director, Mirka

Questions and Answers:

Being net carbon negative means that the net effect of the carbon sequestration of a product, company, locality or country is such that it prevents or slows down climate change. In practice, more carbon is removed from the atmosphere than is emitted into it, so the number of emissions is negative. In the Mirka SHAPE project the aim is exactly this; develop remanufacturing and refurbishing technologies prolonging binding carbon throughout the value chain resulting in net carbon negative solutions for shaping and finishing surfaces.

Source: Sitra

The green transition means a shift towards economically sustainable growth and an economy that is not based on fossil fuels and overconsumption of natural resources. A sustainable economy relies on low-carbon solutions that promote a circular economy and biodiversity.

For companies, the manufacturing industry and municipalities, the green transition can mean investments in clean energy production, circular economy solutions and hydrogen technology, and the introduction of different kinds of new services and operating models.

Source: Ministry of the Environment in Finland

Remanufacturing means reusing or repairing components in order to rebuild old products. Hence the lifetime of the product is extended and the need of producing a new one is unnecessary.

In the SHAPE project, the ecosystem will consist of companies of different sizes as well as research groups, universities and other players. The aim of the ecosystem is to achieve the target of the SHAPE project by sharing knowledge and competence across industry borders.

An economic model which does not focus on producing more and more goods, but in which consumption is based on sharing, renting and recycling. Materials are not destroyed in the end but are used to make new products over and over again.

Source: Sitra

Sustainable materials are materials used throughout our consumer and industrial economy that can be produced in required volumes without depleting non-renewable resources and without disrupting the established steady-state equilibrium of the environment and key natural resource systems. Sustainable materials are materials from renewable sources that can be produced at high volumes without adversely affecting the environment or critical ecologies.

Source: Rutgers

The integration of environmental aspects into the product development process, by balancing ecological and economic requirements. Ecodesign considers environmental aspects at all stages of the product development process, striving for products which make the lowest possible environmental impact throughout the product life cycle.

Source: European Environment Agency

A value chain refers to the full lifecycle of a product or process, including material sourcing, production, consumption and disposal/recycling processes.

Source: University of Cambridge

Shortly about Business Finland

Business Finland is a public organization providing internationalization and funding services to companies, accelerating sustainable growth, and generating prosperity and well-being for Finnish society. Business Finland helps customer companies grow and succeed globally, develop solutions for the future and renew their business operations boldly. The aim is to promote collaboration between companies and research groups so that new endeavours can develop into international business ecosystems.

The Business Finland Challenge Competition “Veturi”

Each year Business Finland launches challenge competitions in which companies with international operations agree to resolve significant future challenges and increase their research, development, and innovation investments in Finland. The winner will lead ecosystems that consist of companies of different sizes and other players to further enhance innovation in their field of business.

Contact Details

For more information, please contact:

Mats Sundell

Research and Development Director, Mirka

mats.sundell@mirka.com, phone +358 40 094 8019

Charlotta Risku

General Manager, Mirka

charlotta.risku@mirka.com, phone +358 40 526 3623