2+1 years

Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register, manage and order repair for your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

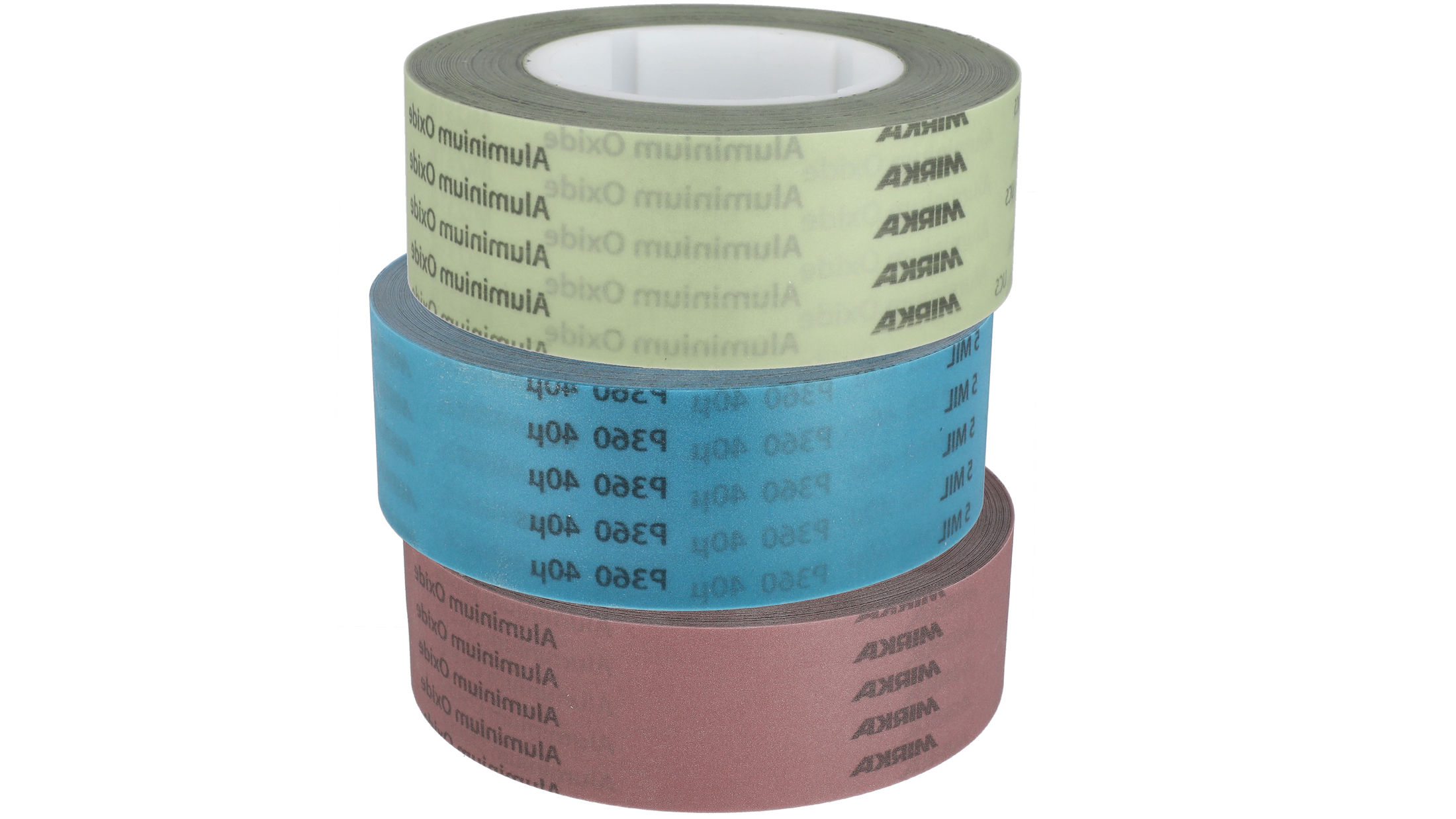

Introducing Mirka MI231B abrasive film for enhanced durability and performance

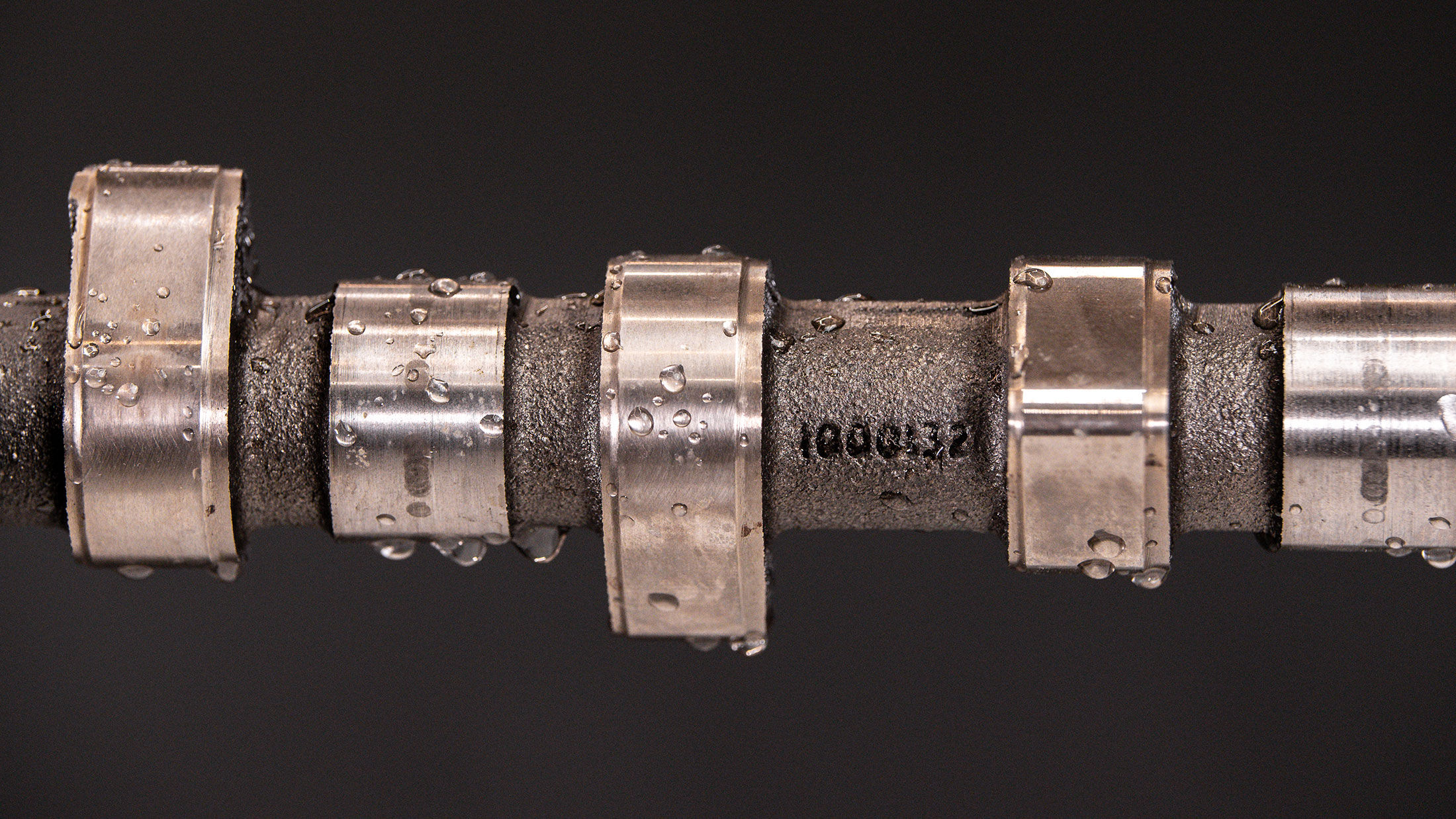

Mirka MI231B abrasive films are engineered to address the critical challenges of powertrain production, including frequent roll changes, machine stoppages, and inconsistent results. Featuring advanced anti-slip technology, these films ensure extended roll life, reduced interruptions, and increased operational efficiency.

Specifically designed for demanding applications such as crankshaft and camshaft polishing, as well as roller conditioning, MI231B delivers consistent, high-quality finishes that improve throughput and reduce production costs.

Optimize your powertrain manufacturing processes with MI231B — the reliable solution for precision and performance.

Mirka® Cafro vitrified CBN superabrasive wheels are the right choice to make your grinding operations more efficient. See the benefits of faster grinding times, improved wheel life, increased dressing intervals, and superior thermal control reflected in a reduced cost per component.

Our vitrified CBN wheels are available in a wide range of customizable dimensions, up to a diameter of 600mm as single-rim wheels and 900mm as segmented. Standard sizes can be produced with an improved delivery time. We offer wheels with steel, bakelite, and carbon fiber bodies.

Mirka’s abrasive films are what you need to achieve consistent functional surface values in your superfinishing or polishing operation. Featuring an anti-slip dot pattern on the back, we offer two different film products to help you easily select the right product for your specific polishing needs.

Our understanding of the powertrain industry and its challenges provides a solid foundation for comprehensive service and cooperation. We offer a global partnership with local technical and sales support that you can rely on. Fast, flexible, and reliable deliveries are key to any industrial process; as such, Mirka’s products are rapidly produced against the customers’ orders and supplied through our own global warehousing and logistic network.

For you and the environment

For us, it has always been clear to not waste financial or material resources – our own or yours. It is equally clear to preserve the planet’s resources. Sustainability, for us, means taking the economy, the earth, and people into consideration when we make business decisions.

We work hard to conserve energy and raw materials, reduce waste, increase recycling, and decrease the use of persistent chemicals. We are developing healthier, safer, and more efficient products and processes so that you will benefit. For example, our dust-free sanding systems help protect the lungs when sanding while giving a cleaner and better surface finish.

For Mirka corporate responsibility is at the very core of how we conduct business. As stated in our values, all parts of our operations are driven to be responsible, committed, innovative and respectful.

In practice, this means ensuring that what we do in terms of sustainability, occupational health and safety, compliance and legislation as well as management systems are an integral part of every department.