Register Your Tool

All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of purchase.

Keep your tools in excellent shape on myMirka where you can register your tools.

Replenish your stock, access marketing materials, view sales guides and read about upcoming product launches.

Pioneers of dust-free sanding

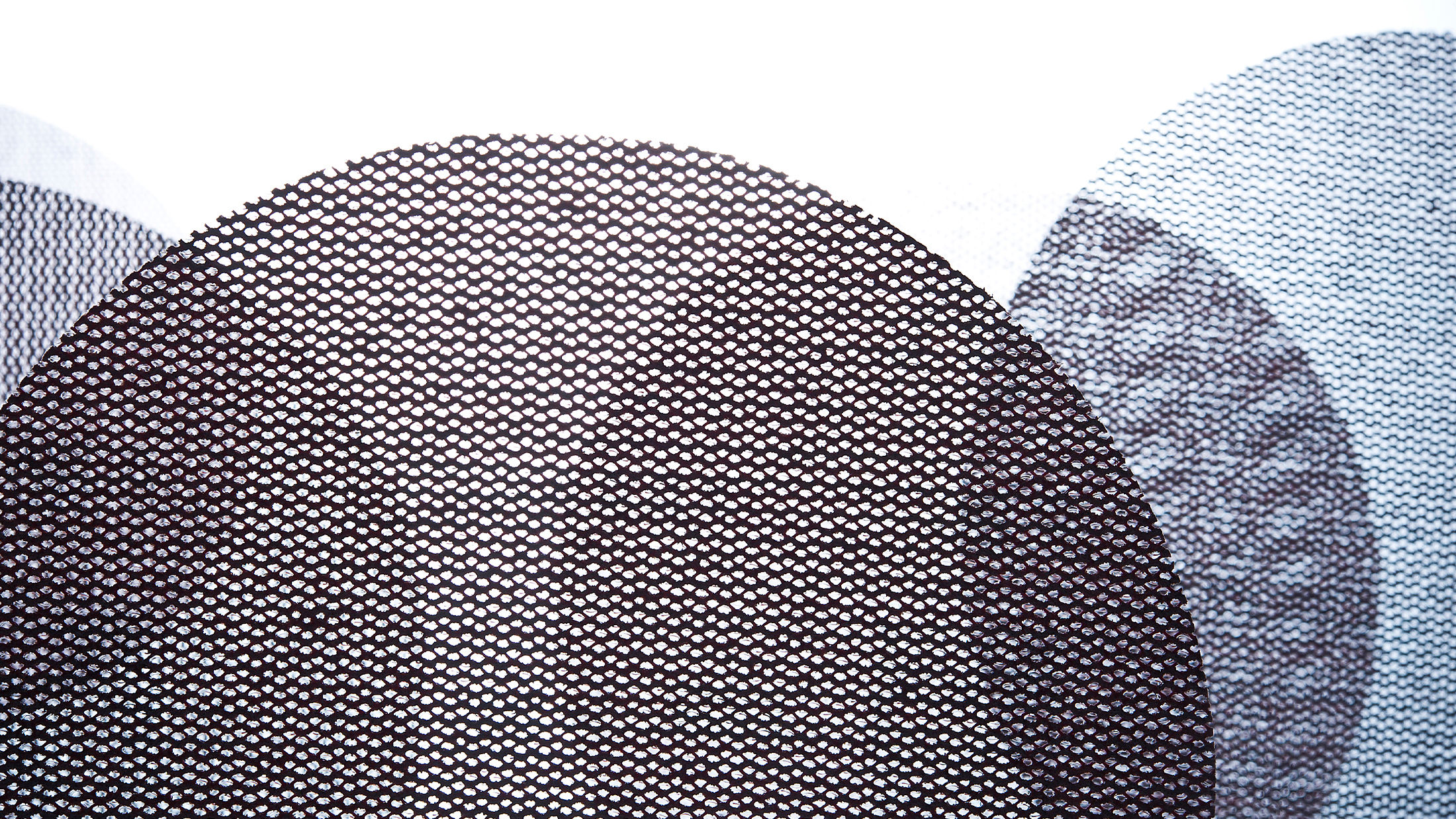

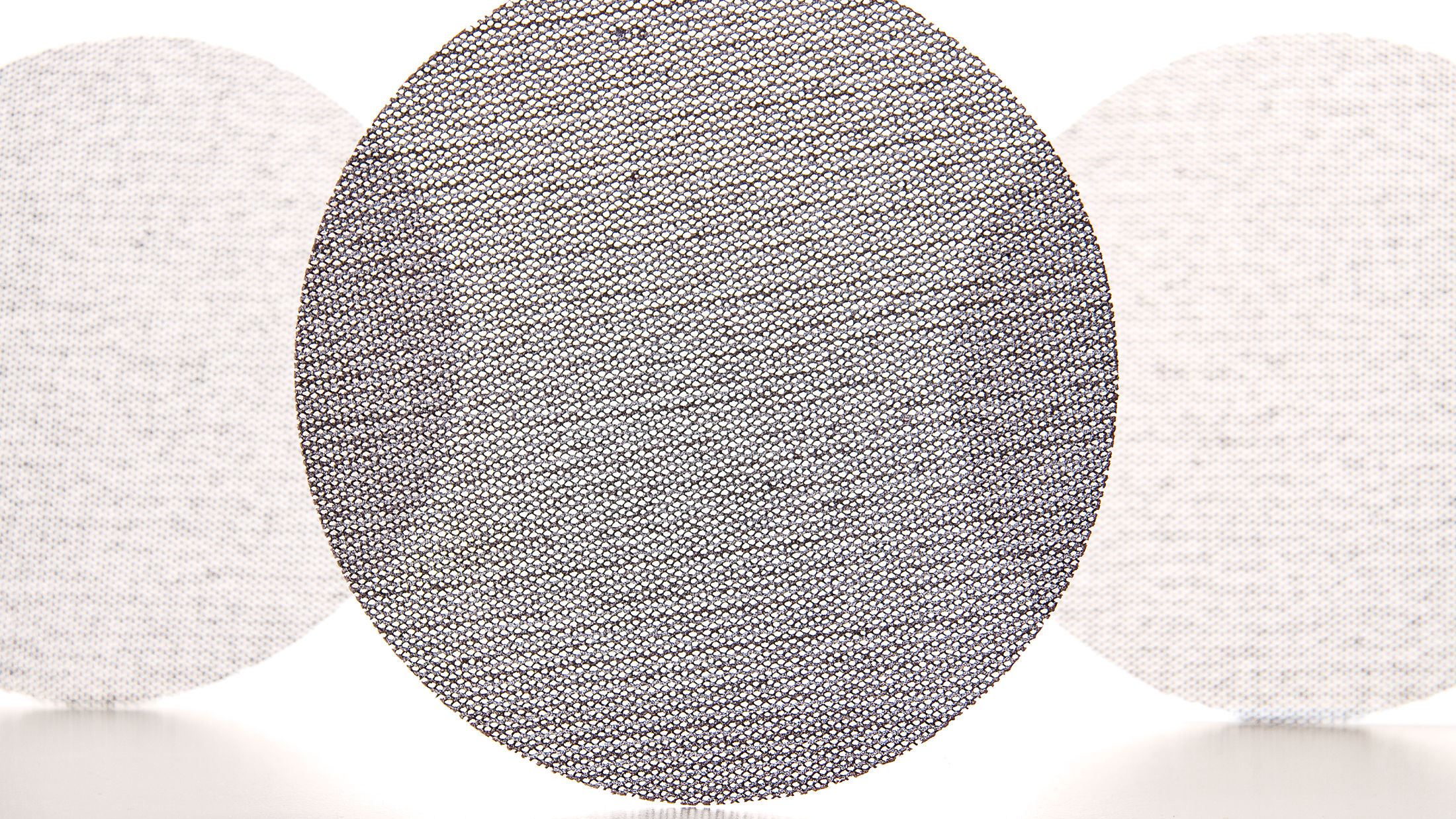

Net Abrasives are an improtant part of the Mirka dust-free sanding solution in their various sizes, forms and grit options.

Abranet features a net structure instead of a conventional paper backing. This results in extremely efficient on-tool dust removal that improves both the work quality and the working environment. The Abranet abrasive product family has expanded to cover many different areas of sanding.

>> Dust-free sanding for a healthier working place

>> Saves time - No dust, reduces time cleaning

>> For a wide range of applications

>> Long lasting

>> High-quality finish

Examples of net abrasives: Abranet, Abranet Ace and Abranet Ace HD

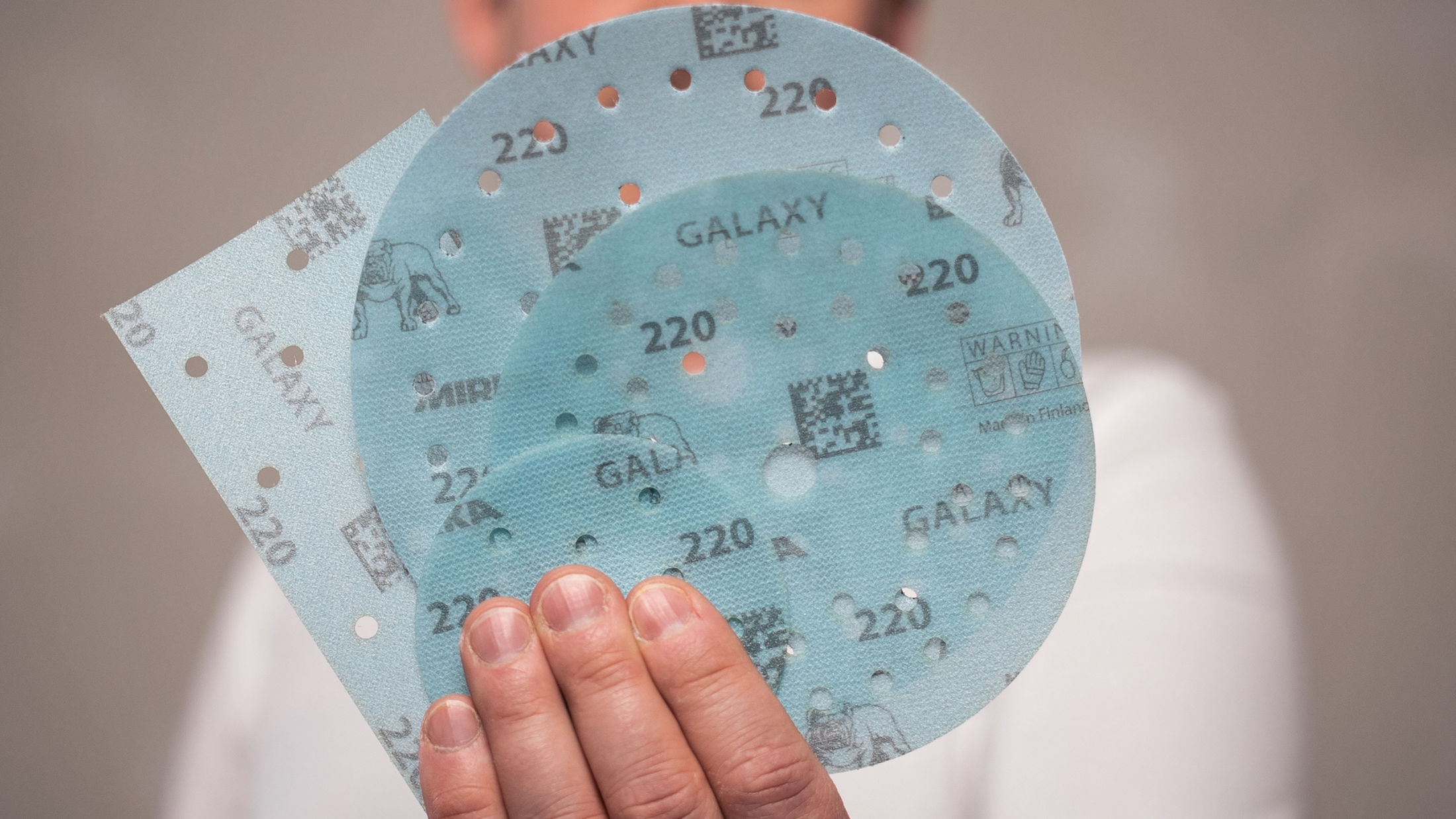

>> Sturdy backing for long life

>> Multifunctional

>> Clog-resistant & dustless

>> This backing for flexible sanding

>> Fast Cut

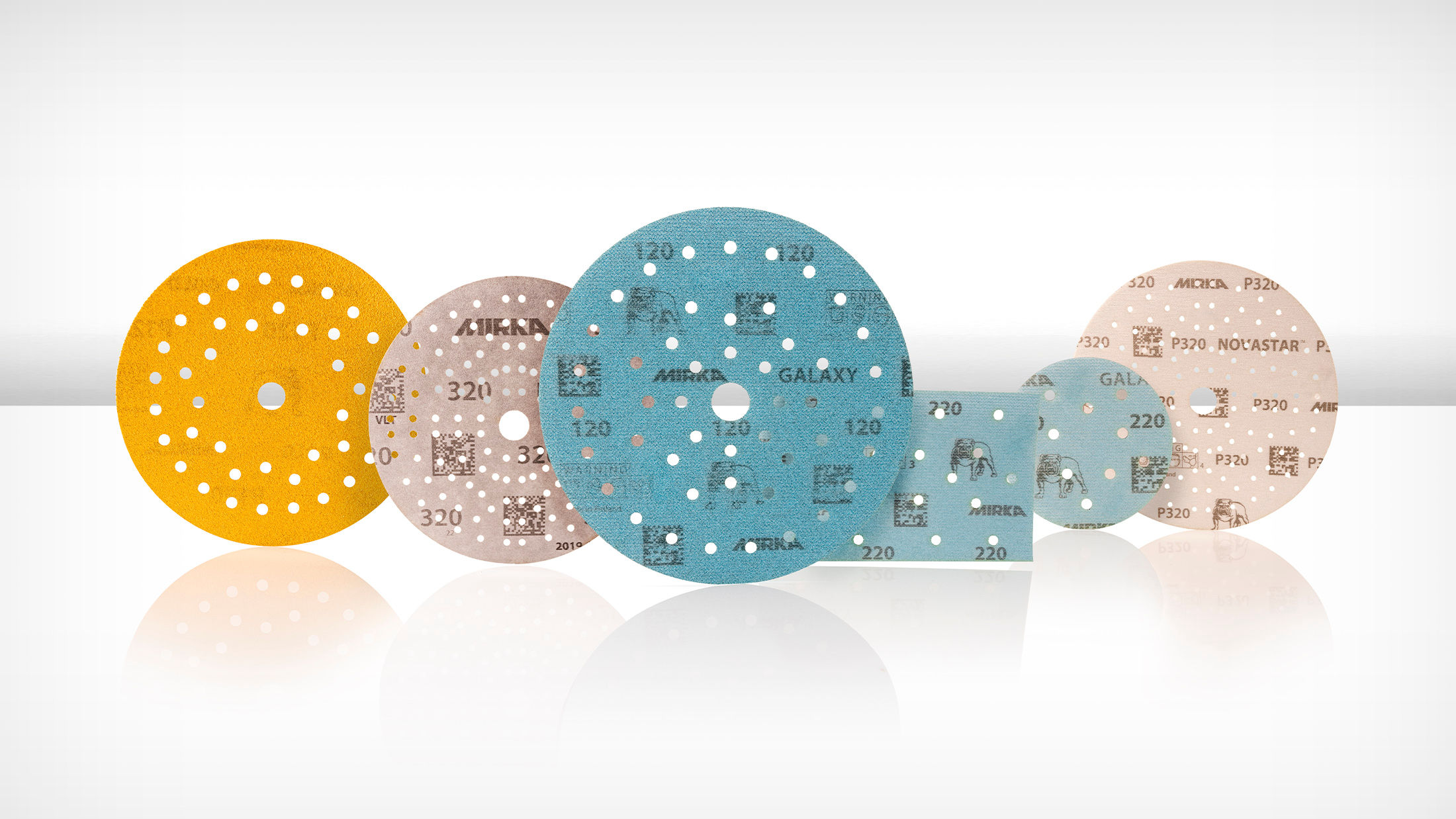

Examples of film abrasives: Galaxy and Microstar®

>> Use Multifit for dustless sanding

>> Wide application range

>> Perfected for speed and efficiency

>> Flexible and durable

>> For both soft and hard surfaces

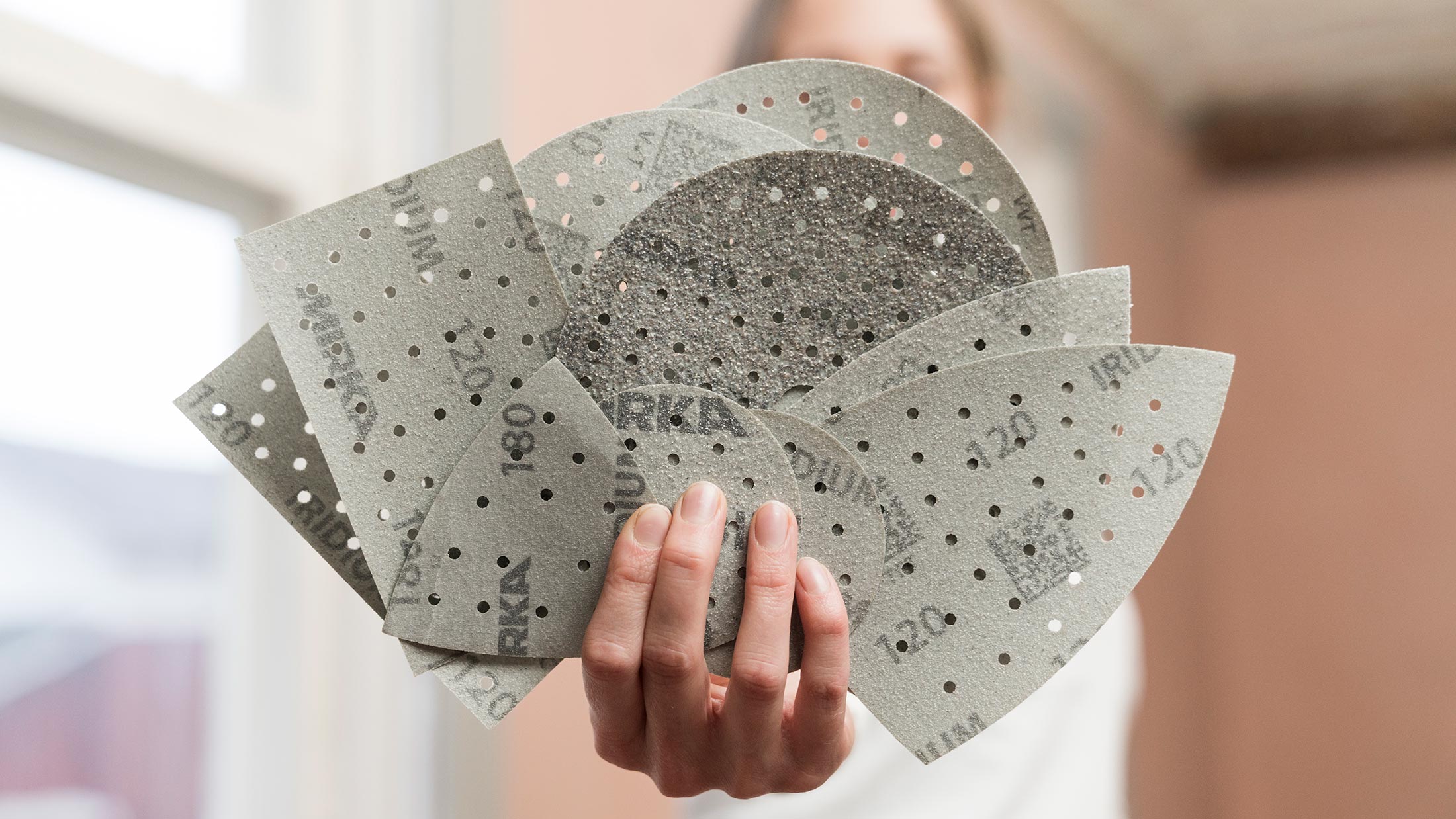

Examples of paper abrasives: Iridium and Gold.

>> For smooth and profiled surfaces

>> The flexible backing minimises the risk of pressure marks

>> Suitable for both wet and dry sanding

Examples of foam abrasives: Abralon, Abralon J3, Goldflex Soft.

>> Three-Dimensional fibre material

>> Long lasting and flexible

>> Used for the final steps in sanding applications for an excellent finish

>> Suitable for both dry and wet sanding

Examples of non-woven abrasives: Mirlon and Mirlon Total

My projects are constantly evolving, and I want to use tools and abrasives that can evolve with them, which is what Mirka can offer. Since I started using them, I have not looked back, and I would recommend them to anyone who asks my opinion about them.

Illuka London

All-New Abrasive for Wood

The first abrasive developed purely for the woodworking sector is designed with an ‘hourglass’ pattern which demonstrates unparalleled performance and effectiveness on wood substrates to ensure optimal material removal, surface finish quality and durability, and sustainability.

Ultimax® Ligno combines innovation with robust consideration for the environment. The production method reduces energy consumption as the process for curing the glue is more efficient. It also has superior adhesion with low VOC resin, ensuring a safer and healthier choice for both users and the environment.

Stop thinking abrasives

Using the right abrasives for the job at hand will reduce waste and increase efficiency.

We believe at Mirka that what we sell is more than just an excellent range of abrasives. To support this, Mirka has a national team of trained staff who have repair industry work experience. With this level of expertise and a proactive, hands on approach to problem solving, waste will be driven down and efficiencies up ensuring a consistent quality of work and increased profitability.

Available from coarse to very fine grits

Mirka's non-woven and flexible conditioning belts are robust and highly adaptive, and they leave an especially good surface finish for the next step.

Not only do the conditioning belts work at a lower surface temperature than traditional file belts, they also leave a satin finish which is free from irregular scratches, making the next step easier for the operator. The sanding process produces no sparks, which is an important factor in many applications.

For all your sanding applications

We offer a complete range of technically superior and high-quality abrasives for all kinds of sanding applications. As a world leader in surface finishing technology, Mirka provides a broad range of ground-breaking abrasives and sanding solutions for professionals in surface finishing and the precision industry. We manufacture cloth, coated, fibre, film, foam, non-woven, sandpaper and dust-free net sanding abrasives.

With dust minimized, you can focus on what you do best; knowing that our abrasives provide a more cost-efficient, safer, cleaner, and healthier working environment. Our extensive abrasive product range caters to both individual operations and complete sanding systems.

Sanding Process

On a miniature scale, the individual abrasive particles cut material from the object being sanded. The dust particles that result from sanding wood, for example, are merely microscopic versions of the sawdust and shavings produced by larger-scale wood-cutting processes. There are also abrasives for metal and other materials and sanding applications that work in the same way.

The abrasives, like the sanders, do exactly what they say on the tin. The Abranet ACE offers us high quality dust extraction combined with the sanders which allows our employees to work in a safe dust-free environment, whilst the Abralon gives us a high quality consistent finish, which is paramount in our industry and for the products we produce.

Simply Solid

Making abrasives involves chemistry, physics, and materials science

All these factors need to be considered to produce suitable coatings. The size and properties, as well as the orientation of the “grit” particles as they are deposited on the adhesive-coated backing, and the properties of the adhesive and backing materials themselves – all these factors need to be considered to produce coatings that are fit.

Grains of aluminium oxide and silicon carbide are commonly used as the material and resin adhesive is typically used to bond the grains to the backing paper. The range of materials, situations, and conditions in the workplace where sanding is required is matched by the large range of coated abrasives available to do the work, each with a unique combination of materials: the size of the grains; open or closed coat – how densely the grains are packed; whether there is a stearate coating to lubricate and prevent clogging; the flexibility (or rigidity) of the backing material; and its suitability for dry or wet sanding.

There is more to sandpaper

When it comes to sanding the choice of abrasive grain is vital, both for the final result and to achieve the best possible lifespan from the product. Choosing a sharp grain will achieve a good cut, however if a finer surface finish is essential then another type of grain may be chosen. The grain selection process is also affected by the strength required.

The most common abrasive grain for sanding is aluminium oxide – the grains are sharp and tough enough for most applications.

Compared to aluminium oxide, silicon carbide is more regular in shape and is not as brittle. The strength of these abrasive grains makes it perform well on hard surfaces. In addition, the shape of the silicon carbide grains produces a better surface finish compared to aluminium oxide, which makes them more suitable for intermediate sanding.

Special ceramic grains can form new abrasive edges when it wears down so that you can continue sanding for longer. Ceramic abrasives are designed for hard materials and coatings such as hardwood or solid surface.

There is more to sandpaper

Some abrasives receive a special stearate coating treatment which is designed to prolong lifespan. Usually the stearate is based on zinc or calcium and is like small flakes applied on top of the abrasive.

BENEFITS:

>> As the stearate coating is worn off during use it prevents clogging

and gives the abrasive a longer lifespan.

>> The stearate reduces the initial cut and, therefore, produces a more

consistant surface finish over the lifetime of the product.

Typical Mirka stearated products include Gold, Q.Silver, Abranet and Sica Fine Stearate. Stearated products achieve best results when sanding paint, lacquer and similar surfaces. For coarse sanding with high sanding pressure (for example, wood sanding with wide belts), stearate provides no advantage because it is very quickly worn off.

Is your sandpaper clogging?

>> Check that the paint, lacquer or filler is properly cured.

>> A stearated product is usually the best choice for paint or lacquer.

>> Use machines with dust extraction and ensure the hole combination on the backing pad is compatible with the abrasive.

>> Avoid sanding with grits that are too fine.

Problems with profile sanding

>> Use specialty abrasives, such as Goldflex-Soft or Mirlon Total for sanding profiled surfaces as they distribute the sanding pressure evenly.

Visible scratches

>> Avoid too big a step between grits.

>> Silicon carbide abrasives will usually give a better surface finish.

>> Use a random orbital sander.

Inefficiency

>> Aluminium oxide abrasives tend to have a better cut.

>> Start with coarse grits and work towards finer grits.

As we use multiple tools and abrasives for our work, we feel that Mirka provides a breadth of products that is unmatched and meets our constantly changing needs and requirements. It also has a support network that we can easily access if we have any issues or questions.

Freeney Graphics

Choosing the appropriate sanding belt can be a challenge, you want to make sure to have the optimal abrasive for your sanding application and surface, otherwise you can damage both the surface and your belt sander.

Here you can learn more about what kind of we belt we recommend for your surface for the job.